Read more

Read more

Overlapping surfaces

Avoid overlapping surfaces as much as possible. If this is not possible, strictly follow the drilling instructions.

Read more

Read more

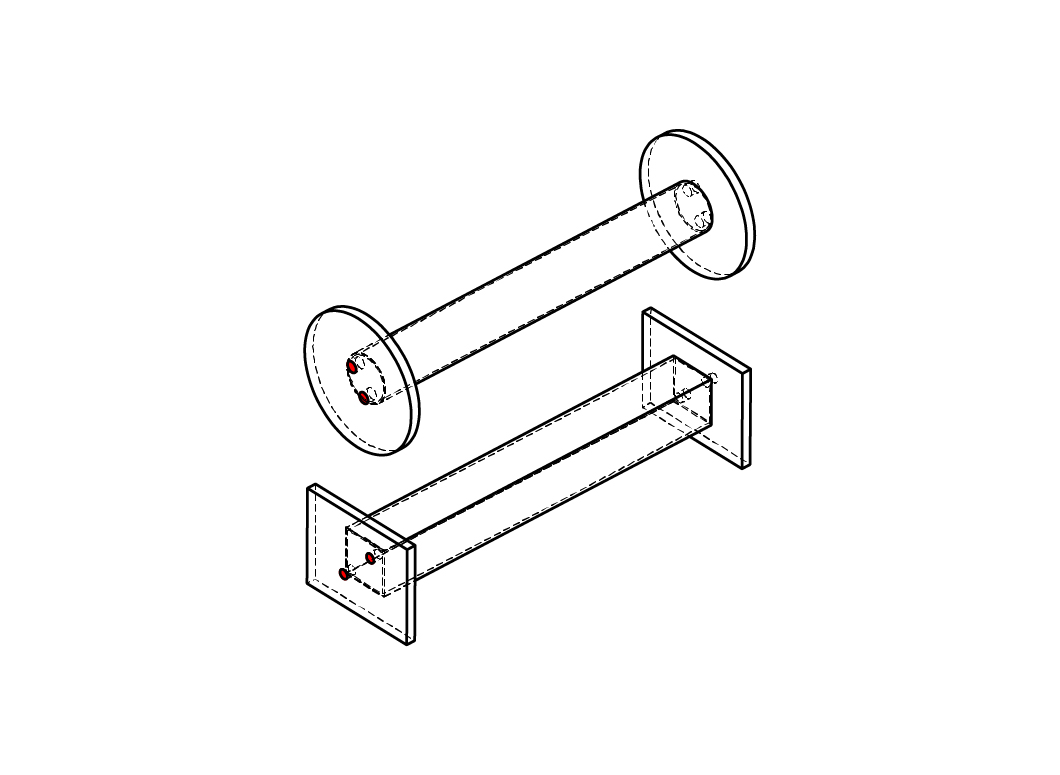

Direction of holes

Place the holes as close to corners as possible! As well proper direction of holes should be considered. It heps the galvanizer if the holes all drain in the same direction. This avoids manipulating and turning of the article with risk of damage or trapping zinc in pockets.

Read more

Read more

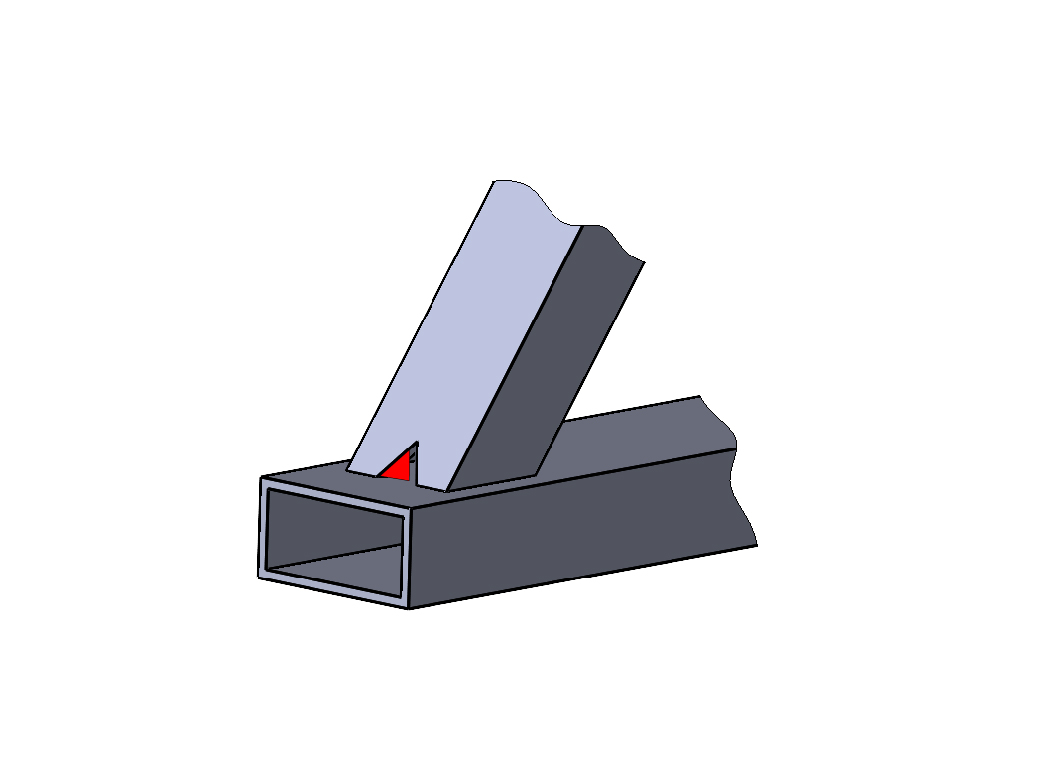

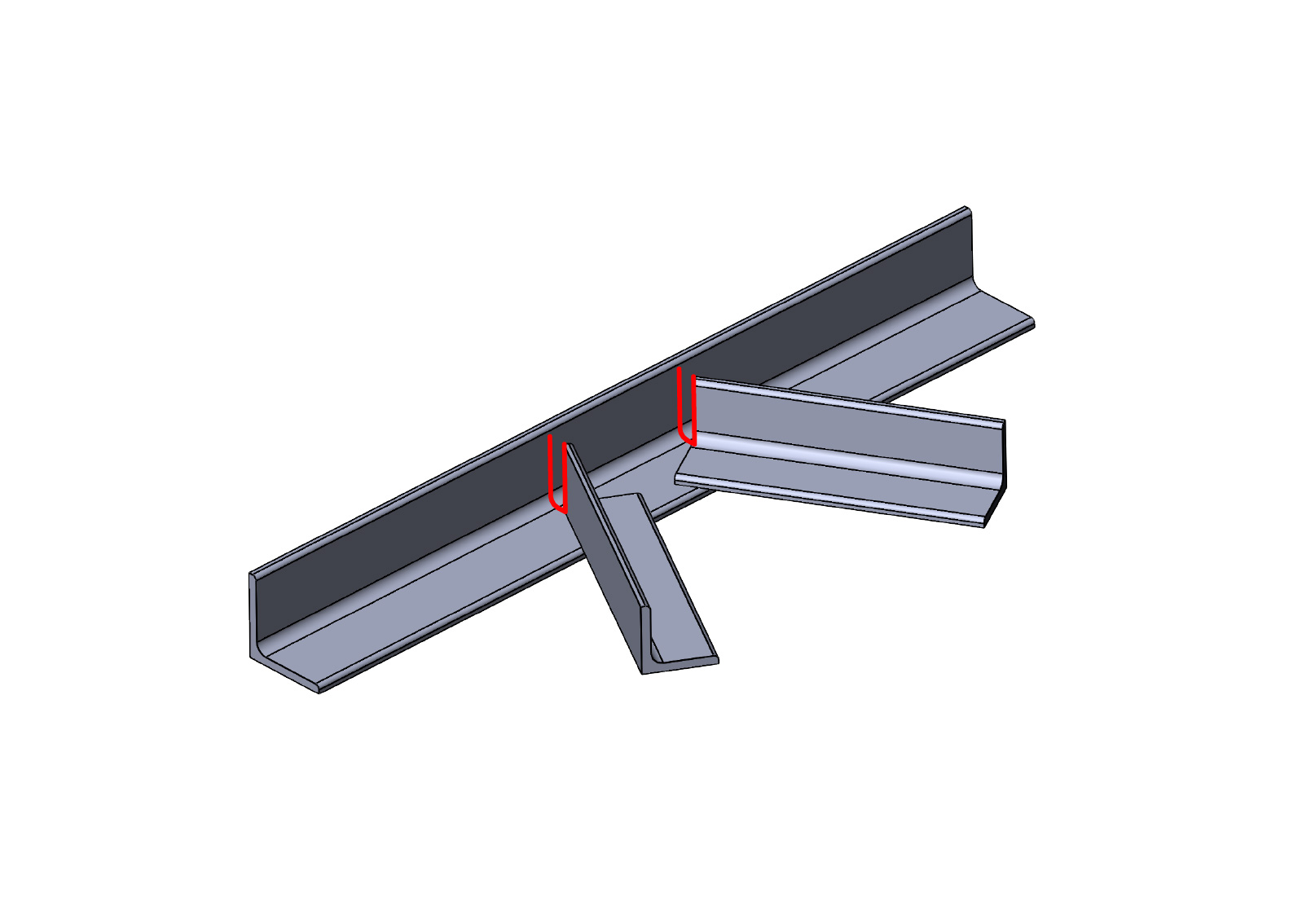

“V”-type notch

“V”-type notch is a good alternative to drilled holes.

Read more

Read more

Stiffeners and gusset plates

Always design stiffeners and gusset plates so that zinc cannot be trapped in corners.

Read more

Read more

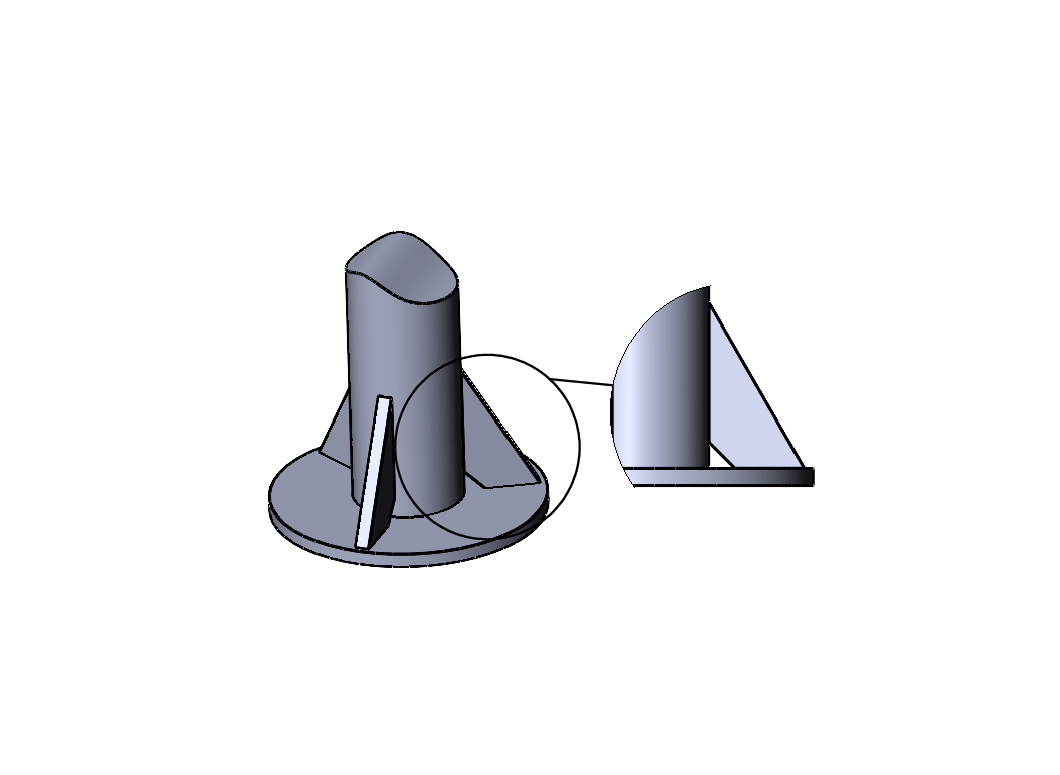

External props

When you use external props, for instance, between a base plate and a vertical element, make sure the prop is cropped to allow zinc to drain freely.

Read more

Read more

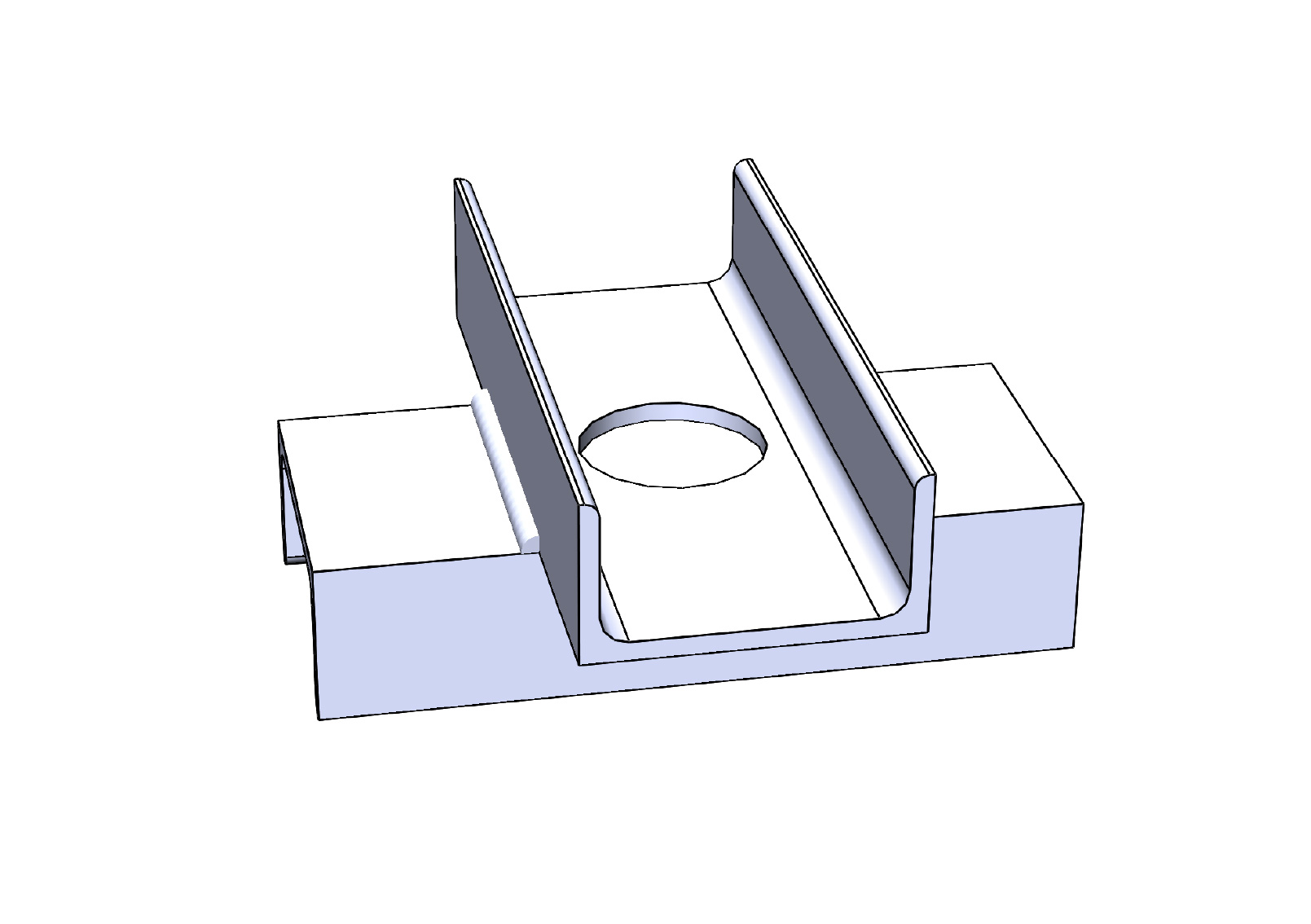

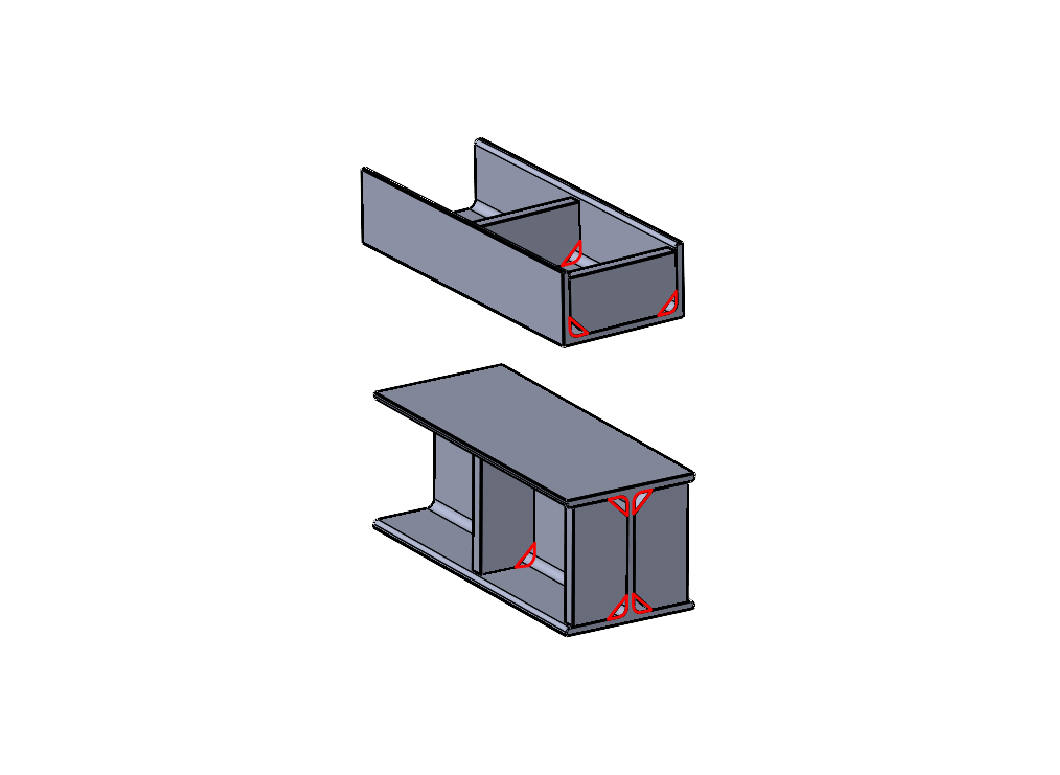

Universal sections or channels

On universal sections or channels, make sure that the corners of stiffeners are cut to allow zinc to drain through.

Read more

Read more

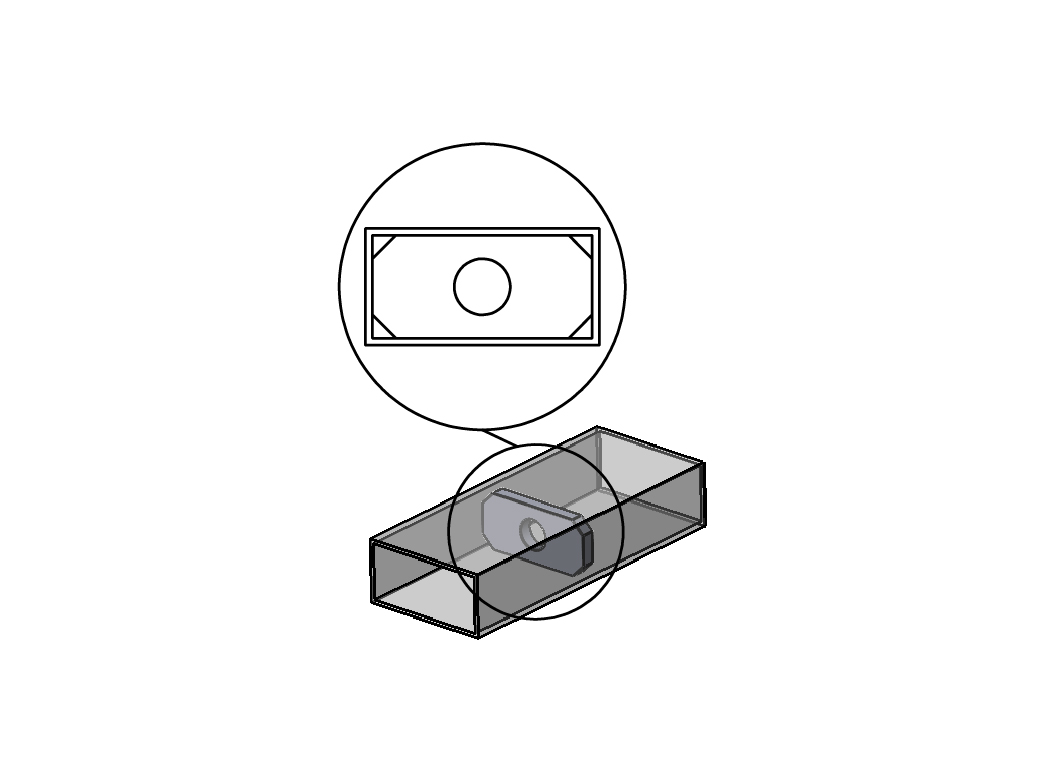

Internal diaphragm

When using internal diaphragm, make sure the corners of it are cut. On larger RHS use a stiffener with a central hole as well as cut corners. NEVER arrange a plate that blocks the entire cross section. It may be dangerous during hot dip galvanizing. (One may happen to be unpleasantly surprised when receiving an invoice if the entire section has filled with zinc which cannot escape!)

Read more

Read more

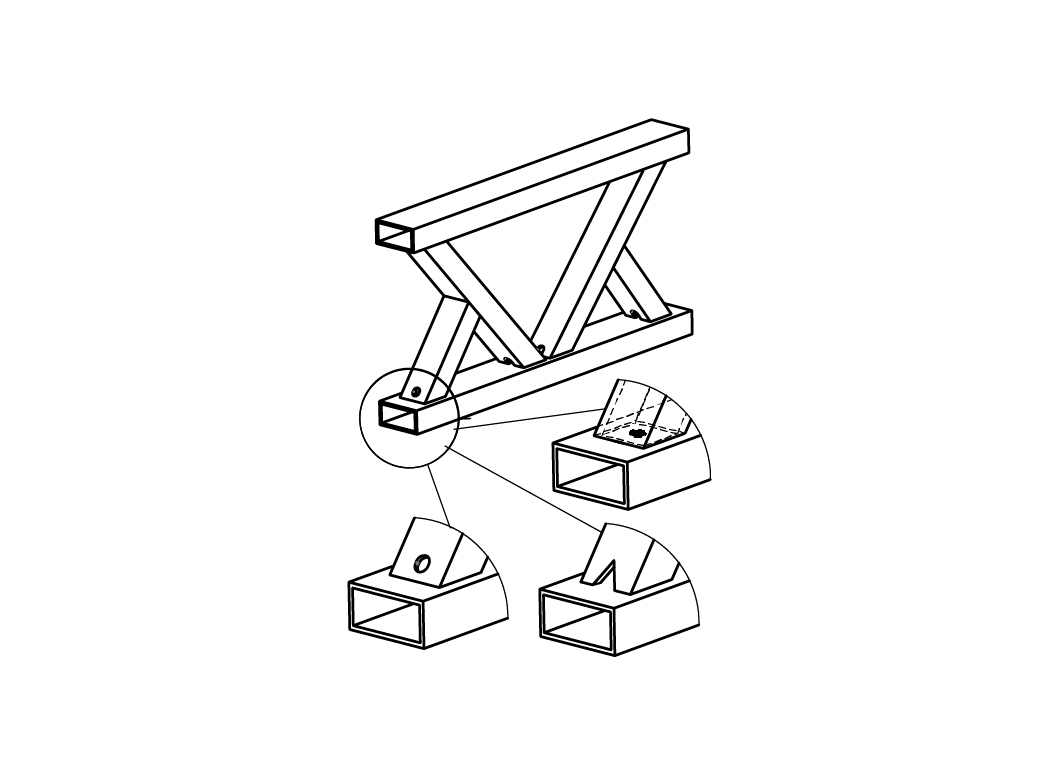

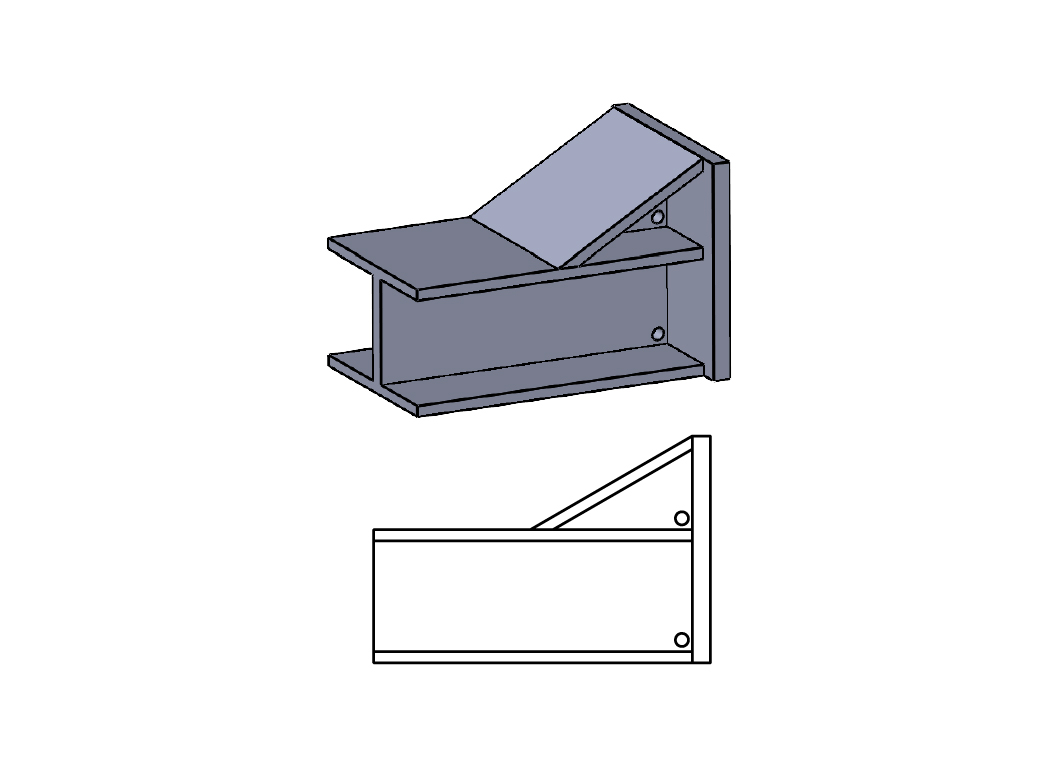

Right-angled supports

When designing right-angled supports or similar structures, holes should be drilled in places indicated in the drawing.